The Electric Eel Wheel Nano 1.1 is an affordable spinning wheel in a travel-friendly package. Its smooth and quiet operation will help you spin gorgeous yarn. Below are a collection of videos that will help you get started using the the EEW Nano.

1

/

2

SPIN #66 – Getting Started with the EEW Nano 1.1

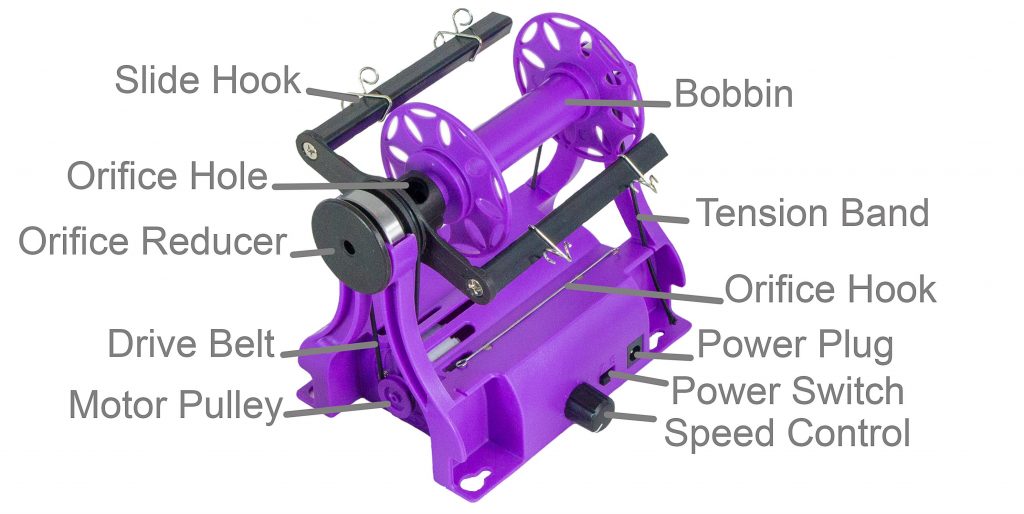

EEW Nano – Getting started 1 – the parts of the nano

EEW Nano – Geting started 2 – choosing fibre

EEW Nano – Getting Started 3 – Preparing to spin

EEW Nano – Getting started 4 – the basics of drafting

EEW Nano – Getting started 5 – plying

EEW Nano Demo & Review

SPIN #65 – EEW Nano 1.1 Update

Spinning cotton on the eew Nano

1

/

2

Replacement Parts and Accessories

We sell EEW Nano replacement parts and motors on our store. This is the easiest way to get replacement parts; however, we also believe in giving you options. Below is information and alternative places to buy the parts on the EEW Nano that aren’t custom made.

- Drive Belt – Size 036 o-ring made of EPDM Rubber

- Tension Band – 1/16 inch Diameter Elastic Cord

- R6-2RSV Bearing (smaller rear bearing)

- 6804-2RS Bearing (larger front bearing)

- Wall Power Cord (9V, 1A, 5.5×2.1mm barrel connector)

- USB Power Cord (USB to 9V, 5.5×2.1mm barrel connector)

Here are some additional videos and links you may find useful:

FAQs

| Is there a good guide to spinning with the EEW Nano for completely new spinners? | Here is an in depth five part getting started video series from Vampy: Part 1, Part 2, Part 3, Part 4, Part 5 Another option is to check out this page of spinning instructors who are willing to do 1 on 1 instructions for the EEW Nano (some are paid and some are volunteers). |

| Are there more complete troubleshooting guides? | Here is a good thread on Ravelry. Here is a good page on Facebook. |

| Why is my motor overheating? | 1) If you are using a battery, make sure you are using the USB cable that comes with the deluxe version. This cable makes sure the battery outputs 9V. Some of the Tallentcell battery packs have a plug that will fit into the EEW Nano, but that runs the motor at 12V and it will overheat. 2) Reduce the tension to a light tension. The elastic tension band usually ships with it too tight so try loosening it. This allows the motor to work less. 3) Make sure the front and rear bearings holding the flyer are fully seated into their slots. 4) Make sure the bobbin is fully pressed together. |

| Why isn’t there uptake? Uptake is the name for yarn being pulled onto the bobbin. | 1) Check to make sure the tension band has a little tension and is resting in the tension band notch on the bobbin. 2) Make sure the yarn isn’t getting caught on the ends of the triangular clamps. Try loosening the screw holding the sliding arms in place, rotating them and then re-tightening the screw. This can give a better path for your yarn. 3) If you over spin your yarn it will get little kinks in it and these will catch on the orifice hole or the sliding hooks. To fix this manually twist the bobbin until the over spun yarn is on the bobbin and start again trying not to over spin the yarn this time. 4) Check to make sure there isn’t something preventing the bobbin from freely spinning. Clean out any yarn or dirt stuck on the inside of the bobbin that might be causing it to be stuck to the flyer. If the bobbin still doesn’t spin freely it might be a slight issue with how that bobbin was moulded. You can fix this by flipping the bobbin around on the flyer or sanding it slightly (a quick way to test for this is just to try a different bobbin). 5) Check to make sure the yarn where it’s tied to the bobbin isn’t slipping. If it is you can use a small piece of tape to prevent it from slipping anymore. 6) Make sure the bobbins disks are pushed all the way onto the bobbin tubes. Sometimes you need to press really hard to get the bobbin to be fully pushed together. 7) If the bobbin disks fit loosely on the bobbin tube they might be spinning and they shouldn’t. To fix this add a few wraps of tape around the end of the bobbin tube and then put the disk on the tube making sure it’s a tight fit. Another option is to glue the disk to the tube. 8) Try using some thin string or thread. Practicing with this should give you a feel for how uptake works. If this is getting uptake it indicates the issue is with your yarn being thicker and that is causing some of the uptake issues. If this doesn’t work it’s one of the issues mentioned above likely causing friction between your bobbin and flyer. |

| Is there a way to make it quieter? | If you prefer a video, then this excellent video takes you through the steps of making the EEW Nano quieter. 1) Add a thin layer of cellophane tape on the flyer where the ends of the bobbin rest. The bobbin must still spin freely. This will help reduce friction and clicking noises. 2) Try pulling out the orifice reducer slightly to see if it’s rubbing on the supports. 3) If there is a plastic seam on the flyer try removing it with fine grit sandpaper . 4) Try adding candle wax or other lubricant on the ends of the bobbins where it rubs on the flyer. 5) Check to see if the front bearing is seated properly as shown in this video. |

| Why are my bobbins too long? | You are putting the bobbin disks onto the tube backwards. Flip the disks around and put them on the tube and it will be the correct size. Take a close look at the bobbin that came assembled and copy that when assembling your bobbins. |

| Is it ok if my flyer arms are not completely straight? | As long as the flyer arms don’t touch the bobbin this is normal. To keep this eSpinner affordable the design used extruded flyer arms which aren’t going to be perfectly straight. One thing you can try is to remove the screw holding the flyer arm in place and then flipping the flyer arm around and screwing it back in place. It might be straighter after doing this. |

| Why doesn’t my EEW spin or spin fast? | 1) Make sure the rubber drive belt is on the motor pulley and the flyer pulley. 2) Check to see if the drive belt is slipping. 3) Make sure the Z-S switch is not in the middle position. 4) Double check your power cord and make sure your battery pack is charged if using one. 5) Check to see if the pulley on your motor is loose. Here is a video that shows options to fix this. If none of this helps use the contact us link at the bottom of this page to see if you need a replacement motor. |

| How do I prevent my bobbins disks from coming off? | The bobbin disks are designed to just press onto the bobbin tube so that they can be assembled and disassembled for easy travel. Sometimes the disks come off a little too easy and will come off while filling it with yarn. The recommended fix for this is to put a small piece of thin tape on the end of the bobbin tube. This will make the disk fit tighter. Another possible fix is to use glue, but then the disks won’t be removable and make sure you get the disk fully on the tube if you do this. |

This page is for the EEW Nano 1.1. Go to this page for the previous EEW Nano 1.0.